본문

Catalytic oxidation

Volatile organic compounds(VOCs) with the properties of volatility, toxicity and diffusivity pose a serious threat to human health and eco-environment.

A wide range of industrial processes generates VOCs as a consequence of using organic compounds as solvents or reactive chemicals. In addition to causing localised odour problems, VOCs are implicated in a wide range of environmentally damaging processes, including the generation of low-level ozone and smog. For this reason legislation has been introduced in many countries setting very low emission limits for VOCs in process exhaust gases. VOCs are generally hydrocarbon based and when destroyed via thermal combustion they are chemically oxidized to form CO2 and H2O.

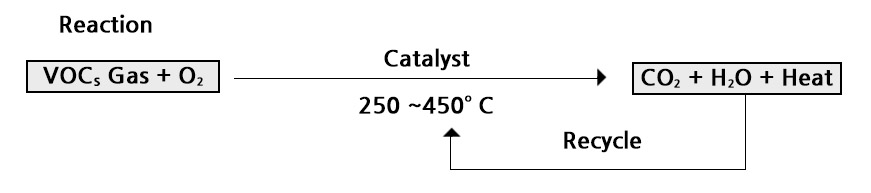

Catalytic oxidation(combustion) has been considered as a highly efficient option for the treatment of VOCs. Catalytic oxidation is well known as one of the means of exhaust gas treatment for VOCs which may cause air pollution, odor problem. It is oxidation reaction between flammable gases such as VOCs and air. In case the gases are hydrocarbons or organic compounds containing oxygen in the structure, they are converted into non-harmful CO2 and H2O by oxidation reaction and it generates heat of reaction for heat recovery.

The Catalytic oxidation have recently been developed which decompose offensive odors using using Mn-Cu metals. The catalytic oxidation is another category of oxidation processes that is similar to typical thermal oxidation, but the catalytic oxidation use a catalyst to promote the oxidation. Instead of using expensive direct heat and high temperatures, catalytic oxidation rely on the chemical effectiveness of catalytic activity to oxidize the pollutants and to remove these problematic substances from exhaust streams. Such catalyst-based processes can remove 99+% of VOC pollutants at temperatures as low as 200∼350°C, and with hardly any additional fuel costs.

Chunghae ENV Co.,Ltd. supplies very efficient catalytic oxidation system that use a technology solution, which has been proven over a number of years to be suitable for the destruction of high levels of VOCs. Catalytic oxidation system also combines very high thermal efficiencies and while minimising operating costs.

Advantages

- High removal efficiency of VOCs

- Complete combustion of CO

- Low temperature combustion

- Low fuel consumption

- Long equipment lifetime

- No secondary pollutants(such as wastewater) to deal with

- Rapid startup and flexible operation that enable you to deal with changing requirements